Products

We always have the right solution for your individual application

Our product range extends in its diversity from standardized sealing solutions to customized special designs.

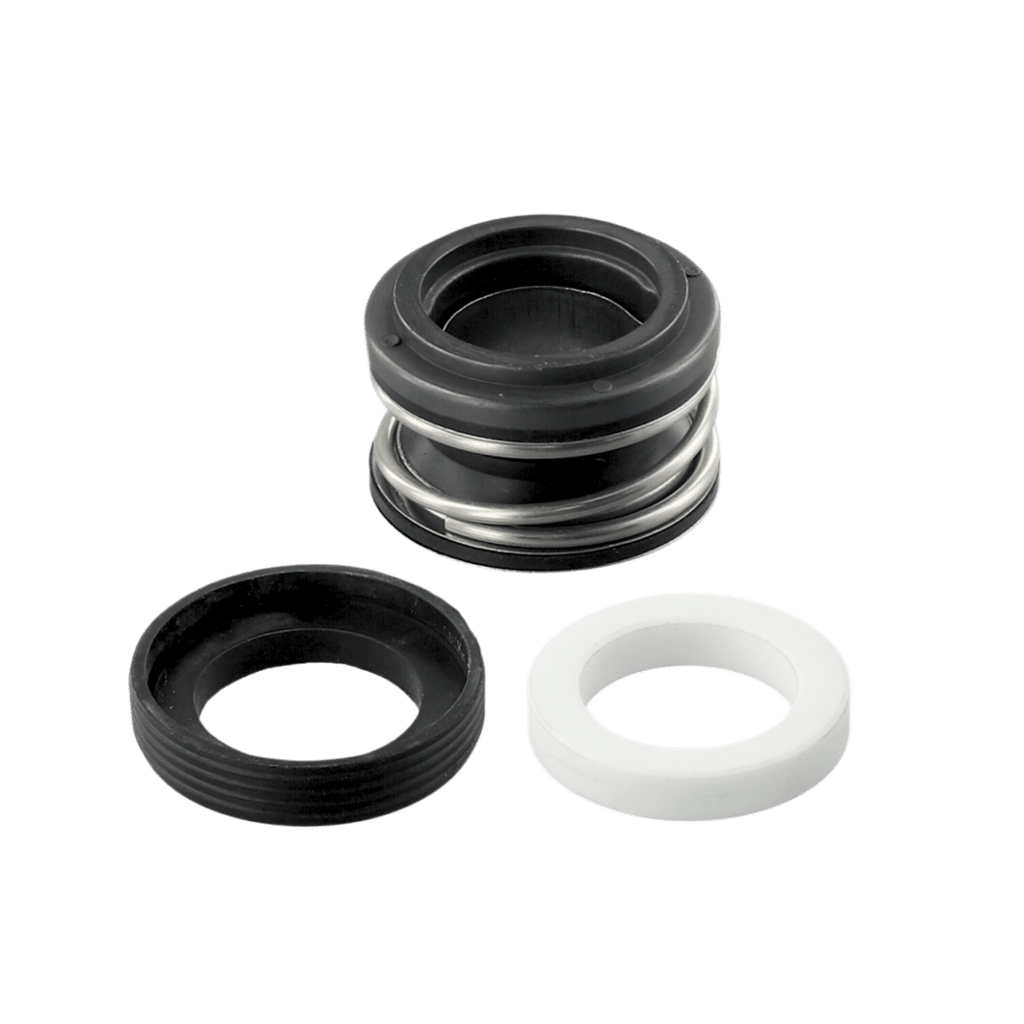

A mechanical seal acts as an effective barrier to prevent liquids or gases from escaping from a rotating machine. It is made of high-quality materials that ensure a low-friction and reliable seal. These seals are able to provide excellent performance even under extreme conditions, making them an indispensable solution to industrial challenges.

A mechanical seal, also known as a sliding seal or stuffing box, is an extremely significant component in numerous industrial applications. In this article, we will discuss in depth what a mechanical seal is and why its role is critical in pumps, rotary machinery and other applications.

The clever design and precise operation of a mechanical seal can avoid potential problems that could otherwise lead to loss of performance and expensive repairs. Their use in pumps, for example, ensures that fluids are pumped efficiently without causing unwanted leakage.

Mechanical seals also play a crucial role in rotary machinery. They help to extend the service life of the machines and minimize unwanted failures. This level of reliability and efficiency is essential in high-quality industrial applications.

Mechanical seals are diverse, with different types including single spring, multi-spring, metal bellows and cartridge seals. But how exactly does each of these seals work? Each type of seal has its own unique mode of operation and advantages and disadvantages. Choosing the right seal depends on the specific application, operating conditions, and individual requirements of your system. In our blog, you'll learn not only how mechanical seals work overall, but also how to make the optimal selection for your requirements.

Single spring seals represent the simplest and most widely used type of mechanical seal. Their operating principle is based on a single spring applying pressure to the rotating and stationary components to create a reliable seal.

Multi-spring mechanical seals are an advanced variant that uses multiple springs to apply uniform pressure to rotating and stationary components. This sophisticated design gives them greater robustness compared to single spring seals and allows them to withstand more demanding pressure and temperature conditions.

Metal bellows seals used in high-pressure applications are a fascinating technology. Their metal bellows adapt to the movement of the shaft, expanding and contracting to provide an efficient seal.

Cartridge seals are an extremely user-friendly solution. They are pre-assembled and easy to install as well as maintain. These seals contain all the necessary components for a mechanical seal and are designed to allow uncomplicated and quick replacement.

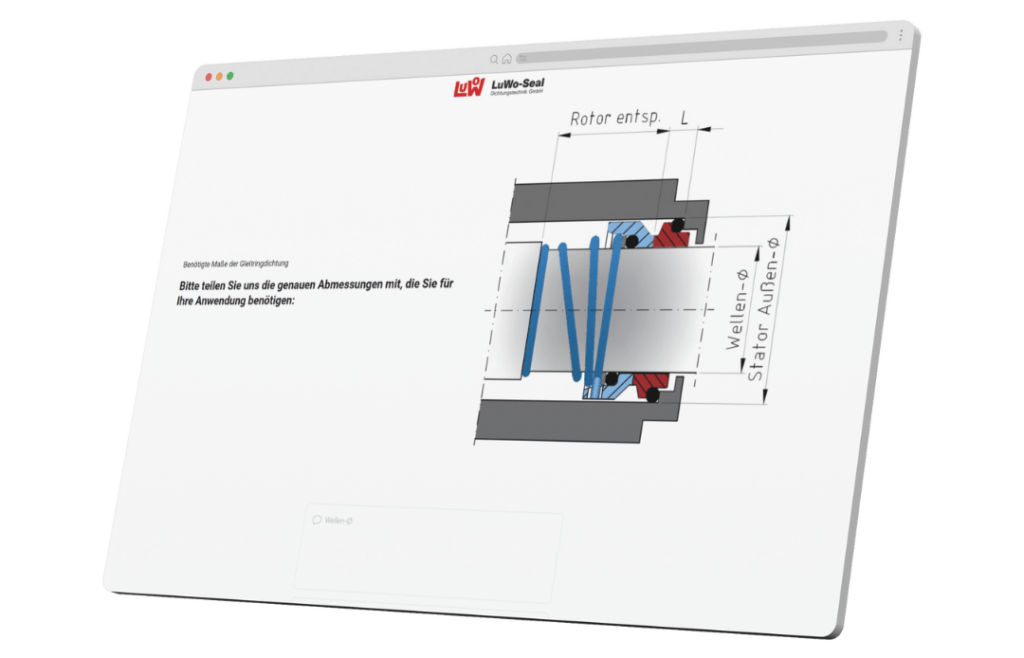

Rührwerksdichtungen – maßgeschneiderte Lösungen für höchste Ansprüche. Jede Dichtung ist individuell auf Rührwerke zugeschnitten, bereits vormontiert und zeichnet sich durch einfache Installation sowie Wartung aus. Unsere Rührwerksdichtungen enthalten sämtliche notwendigen Komponenten für eine effektive Abdichtung und ermöglichen einen unkomplizierten, schnellen Austausch, um Ihren spezifischen Anforderungen gerecht zu werden.

In summary, mechanical seals are much more than a simple component. They are the invisible problem solvers that ensure high-quality and reliable performance in industrial environments without losing their status as indispensable elements.

Our product range extends in its diversity from standardized sealing solutions to customized special designs.