Surface coatings

LuWo-Seal steht für Lösungen, die exakt zu Ihrer Anwendung passen.

LBT-Beschichtungen für maximalen Schutz. Entwickelt für anspruchsvolle Oberflächen.

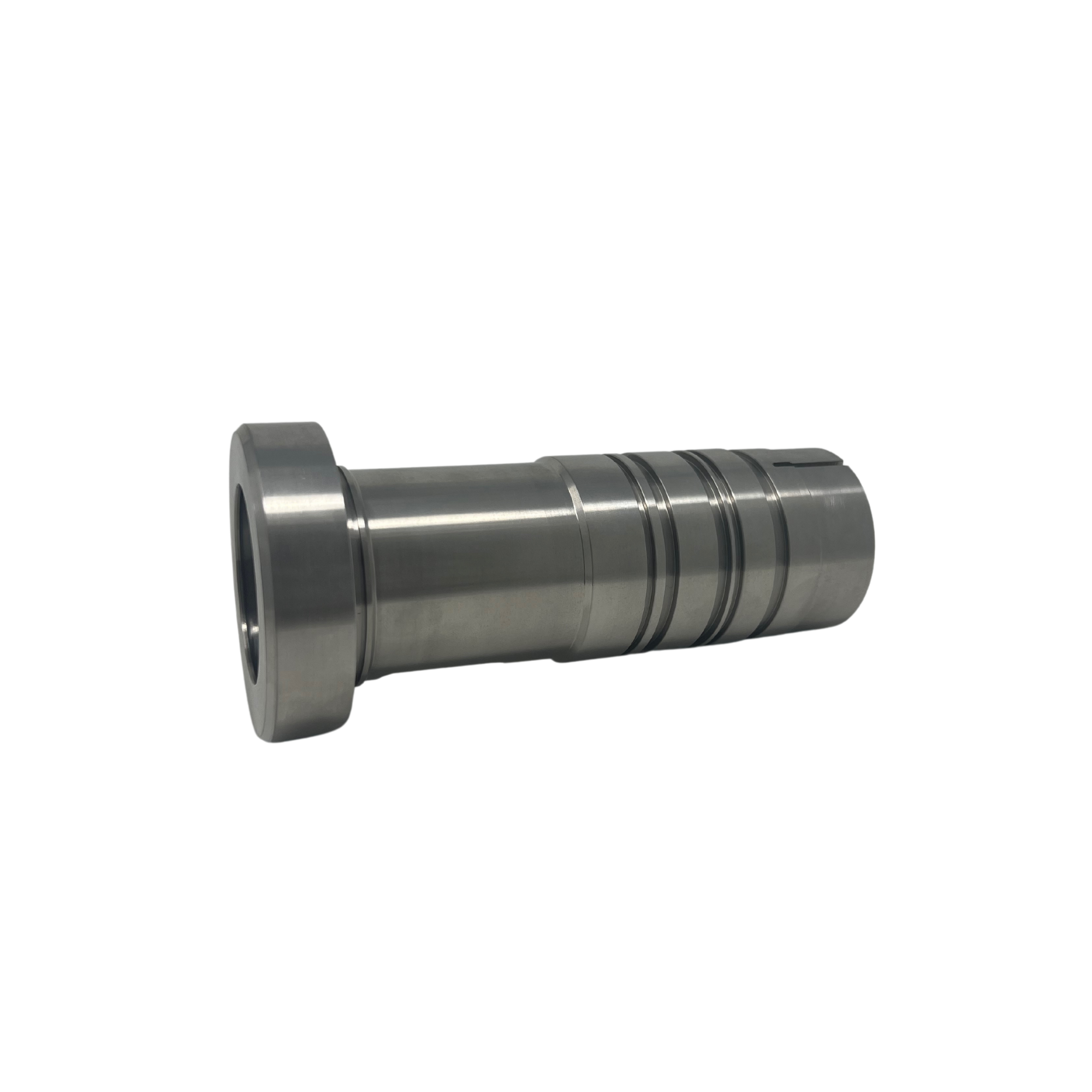

Shaft Coatings

Shaft Sleeve Coatings

Oberflächenlösungen

LBT-211

LBT-148

LBT-404

LBT-231

LBT-170

Chromium oxide , highest wear resistance and corrosion resistance good running properties in combination with elastomers e.g. shaft seals max. layer thickness 0.3 mm, hardness HV 1200.

Nickel alloy without fusible link good wear resistance suitable for all metallic materials. Application: Coating of bearing seats and in the stuffing box area, max. layer thickness 1.5 mm, hardness 43 HRC.

Nickel alloy hard with fusion bond (t= 1040°C) only suitable for weldable base materials. Application: Preferably as coating for new parts with high load, max. layer thickness 0.5 - 0.8 mm, hardness 60 HRC.

High speed coating with chromium carbide/nickel/chromium Application: as improvement to hard chrome plating e.g. for pistons, plungers etc., max. layer thickness 0.2 mm, hardness HV 960.

LBT-211

Chromium oxide , highest wear resistance and corrosion resistance good running properties in combination with elastomers e.g. shaft seals max. layer thickness 0.3 mm, hardness HV 1200.

LBT-148

Nickel alloy without fusible link good wear resistance suitable for all metallic materials. Application: Coating of bearing seats and in the stuffing box area, max. layer thickness 1.5 mm, hardness 43 HRC.

LBT-404

Nickellegierung hart mit Schmelzverbund (t= 1040°C) nur geeignet für schweißbare Grundwerkstoffe. Einsatzbereich: Vorzugsweise als Beschichtung für Neuteile mit hoher Belastung, max. Schichtstärke 0,5 – 0,8 mm, Härte 60 HRC.

LBT-231

High speed coating with chromium carbide/nickel/chromium Application: as improvement to hard chrome plating e.g. for pistons, plungers etc., max. layer thickness 0.2 mm, hardness HV 960.

LBT-170

High speed coating with tungsten carbide/cobalt extremely high wear protection mainly used as coating for new parts, max. coating thickness 0.2 mm, hardness HV 1080.

Your added value

durch eine Oberflächenbeschichtung

Our LBT program enables targeted surface protection for machine parts subject to high physical and chemical stress. By means of various coating processes, we can achieve both significantly increased resistance to wear and corrosion, as well as excellent anti-adhesion effects with simultaneously optimized sliding properties. With our program, we have been a reliable partner for years in the food, printing, chemical and oil and gas industries, among others. Due to the short repair times and cost savings, we offer a considerable advantage over new production. We coat for example: Shaft and shaft protection sleeves, homogenizing pistons, screw conveyors, piston rods, bearing seats, liners, plungers, rotors, agitator shafts, protective bushings.